complete production lines with different physical and chemical production capacities along with their spare parts as agents for major minerals.

mines, establishing infrastructure and providing all operating equipment and production lines under the supervision of a distinguished team of engineers, geologists and trained workers.

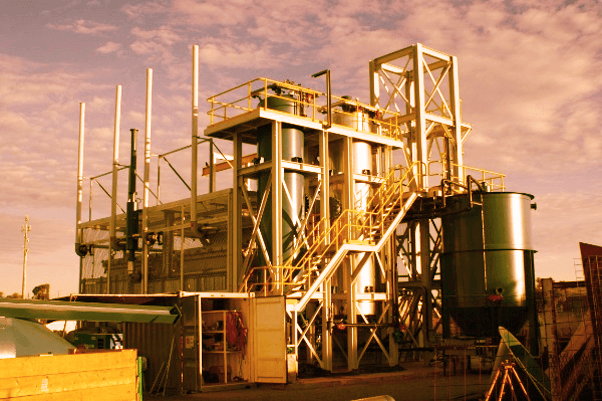

installing and equipping gold extraction lines to control all operating factors.

consultations for different gold extractions solutions with protective and correctional services during the warranty period and beyond

mine operation and management service from the exploration stage up to the production stage.

To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers. Dump trucks haul the rock to the primary crushers in the open pit or to theore stockpiles from underground.

The primary crushers located at the open pit mine site, receive ore and waste at separate times. They break the larger rocks down to a size suitable for transport on the conveyor belt.

A rubber belted conveyor transports the ore and waste rock from the open pit to the mill and waste rock embankments. Large electromagnets remove any steel debris excavated.

Crushed ore from Jaw crusher is fed into the impact crusher ( RDGK) and then to the hammer mill by belt conveyor.

there are different types of physical extraction equipment but all works to concentrate gold taking advantage of its high specific gravity in comparison with other metals. The selection between physical extraction equipment ( Gold Kasha, Gold Cube, shaker tables) or more combined system depends on gold grain size in ore.

The tailing of the physical extraction process stockpiled to Ball mill after lab analysis to resize particles to minimum in order to free micro particles of gold.

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

The loaded carbon is fed into an elution column where the bullion is washed off. The barren carbon is recycled. The wash solution— pregnant electrolyte—is passed through electrowinning cells where gold and silver is won onto stainless steel cathodes.

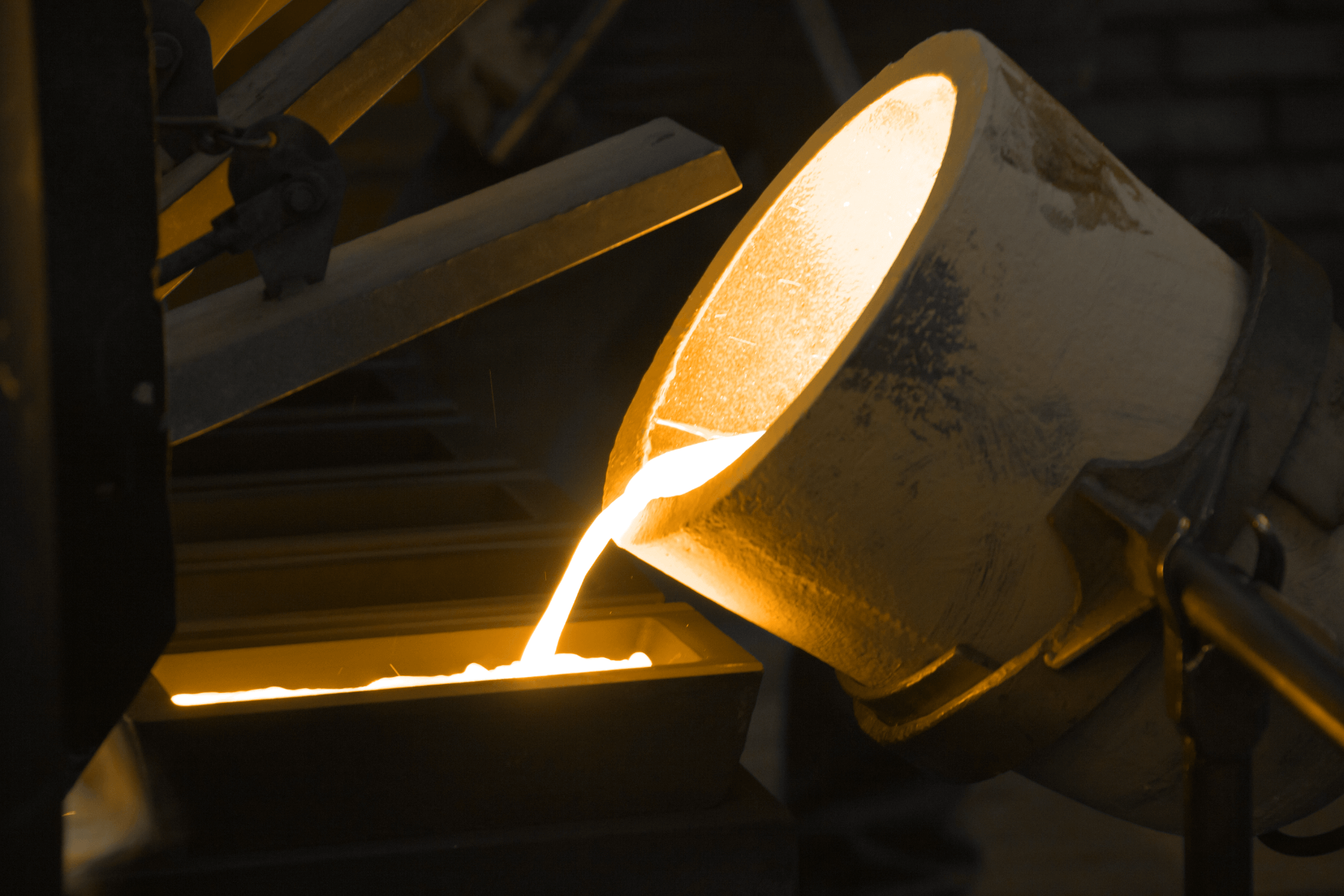

The loaded cathodes are rinsed to yield a gold and silver bearing sludge which is dried, mixed with fluxes and put into the furnace. After several hours, the molten material is poured into a cascade of molds producing bars of doré bullion

Some water from dewatering the mine, from the embankment underdrains and decant water from the tailings pond is recycled for reuse.